Trailed sprayers

The product range contains machines with a tank capacity from 2300 to 15000 litres and spray booms with a working width from 18 to 45 metres. Development, production and distribution are processed according to strict regulations. All AP Dubex machines are SKL tested according to directive NEN-EN-ESO 16122 and are delivered with the approval certificate according to EU regulation 167/2013.

AP DUBEX Actor

Junior

18-27m

Model Junior is the smallest model in our range trailed sprayers.

The Junior is equipped with a 2300 litres tank and a track width of 1500 – 2000 mm.

Vector

18-36m

Model Vector is available in working widths from 18 – 36 m.

This somewhat heavier model comes with a 3200 litres tank, and track widths of 1500 – 2250 mm.

Mentor

18-45m

Model Mentor is the middle brother in our range trailed sprayers, the empty weight is 3250 to 5300 kg.

This model is delivered with a 4000 litres tank and working widths from 18 to 45 m.

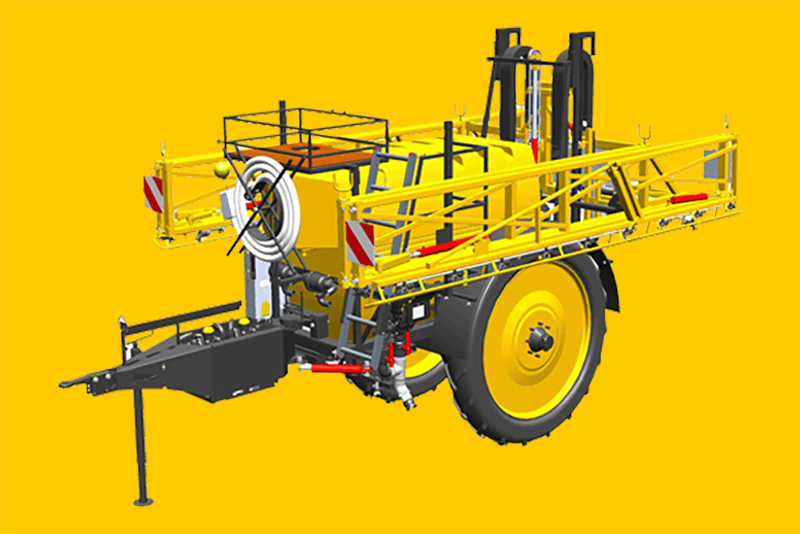

Actor

18-45m

Our absolute all-rounder in the segment, the Actor. Thanks to a tank capacity of 5000 liters and working widths from 18 to 45 m this sprayer will meet all your expectations.

Stentor

24-45m

Model Stentor is the largest model in our range trailed sprayers equipped with polyethylene tanks. This tank has a capacity of no less than 6000 litres, the empty weight of the Stentor is 3800 – 6000 kg.

Maxtor

30-45m

Model Maxtor is a quality machine for heavy-duty work. The Maxtor is equipped with a stainless steel tank with a maximum capacity of 16000 litres and comes as standard with several functions for optimal performance.

The tank

The models Junior, Vector, Mentor, Actor and Stentor are equipped with a light yet strong tank made of polyethylene. The inner surface of polyethylene is very smooth. Together with the effective rinsing nozzles the inside of the tank can be cleaned quickly and easily.

A clean water tank is integrated in the main tank. This functions also as a liquid damper. In combination with the specially shaped top fluid movements are minimalized. Result : stability and safety.

The tank outlet is shaped in such a way that literally all fluid can be sprayed. The current tank content is displayed by an electronic level measurement. This Tank-Control shows the current tank content both on the machine and on the control terminal.

Polyethylene tank

Stainless steel tank

The frame

The frame is robustly constructed and is the backbone of the machine. It provides a solid basis for the spray boom suspension. The axles are generously dimensioned. The combination axle and wheels provides any desired track width. All axles are equipped with a dual-circuit air brake system.

The optional availabe AP DUBEX air suspension not only provides maximum comfort when driving on roads, it also prevents movements from being transmitted tot the booms. Furthermore it reduces the load on the construction. The automatic level control makes sure the optimum suspension is maintained during load changes.

Track following device

The automatic articulated drawbar ensures the wheels accurately follow the track / tramlines within the narrow margins of the cultural sector. Whether the curve is slight or sharp, the track width of the field sprayer remains the same. The automatic drawbar steering is controlled through Trail-Control. Thanks to the proportional hydraulics, steering movements are extremely smooth and at the correct speed.

Axle steering combined with Trail-Control creates a very quiet boom ride on large driving lanes and in the case of large working widths. In automatic mode the sensors of Trail-Control guarantee an accurate track following by registering the position of the drawbar, the driving speed, the curve’s sharpness and the wishes of the driver. Based on these variables the proportional control valve will be steered in such a way that crop damage and unwanted movements are things of the past.

The drawbar can be delivered upon request with a low or a high hitch. A ball coupling is available as an alternative for the drawbar eye.

Track following device

Track following device

Control and cleaning

The agricultural sector uses many, advanced machines of which the operation is often complex and not easy to oversee. AP DUBEX develops her machines in such a way that their operation is logical and intuitive. The latest electronics helps you to easily achieve the best results. Simple calibration and embedded checks make this technology easy to operate.

Valves

All controls and the (optional) induction hopper can be found on the left side of the machine, and can easily be operated, standing next to the machine. Valves placed on top are immediately accessible from the spacious platform. The suction valves determine where the water is generated from, the machine or outside. Each pump has its own suction valve enabling the filling capacity to easily adjust to the applied crop protection product.

Canister flushing

AP DUBEX offers two possibilities for the dosing of plant protection products and the flushing of cans/sacks. As standard, filling and flushing is done above the tank opening. Optionally an induction hopper is available. Together with the controls you can find this device on the left side of the machine.

It is fully equipped with circulation line, injector and cleaning head. After use the filling and rinsing device is folded within the width of the machine.

Spraying

When the field sprayer is equipped with two pumps, one handles spraying and the second handles agitation. The tank selection valve determines whether spray liquid or clean water is used. When the tank contents reach a minimum level the agitator pump will stop automatically. Furthermore, the surplus of the spray pump can be returned to the suction line outside of the tank. This way the spray liquid in the tank comes to rest and foaming is prevented.

Pumps

All AP DUBEX field sprayers are equipped with Bertolini piston diaphragm pumps as standard. These pumps, of proven quality, are reliable and resistant to plant protection products. The pump capacity varies from 210 to 600 litres per minute. The pumps are well protected mounted in the drawbar.

True circulation line

The best of the best! The trailed sprayers of AP DUBEX are equipped as standard with a circulation line including air shut-off nozzle holders.

This high quality circulation line system makes it possible to pump spray liquid or clean water at high pressure through the spray line, without the nozzle bodies opening. The nozzle bodies are opened with compressed air. Without compressed air they are firmly closed. No matter how wide the sprayer is, as soon as the sections open all nozzles open immediately to spray.

The notorious V shape is a thing of the past. When closing a nozzle or section the pressure system immediately reacts and in an instant the set pressure is achieved.

Cleaning

In the top of the tank turbo shaped rinsing nozzles are mounted. They guarantee efficient and effective cleaning of the tank.

Ecoflush and DCS (Dubex Cleaning System)

Would you like to see the cleaning process automated? The trailed sprayer can be equipped with the AP Dubex “Ecoflush” system, a system to rinse the complete machine quickly. The whole flushing process can be operated via the menu in the terminal in combination with the electric valves.

You can also choose a fully automated system, the Dubex Cleaning System. The menu in the terminal then contains several cleaning programs that operate entirely automatically. Most of the rinsing water is sprayed via the booms, the remainder that has returned to the tank via the circulation line, will be automatically discharged by the drain valve underneath the tank. The complete process is carried out while you are driving in the field, so you can leave the plot with a completely rinsed field sprayer.

Computers

AP DUBEX spraying machines are precision machines. Machines that work for you and optimize crop protection. The spray computers are designed to help you operate. Simple, reliable and high-performance!

ISOBUS

ISOBUS is a uniform language, that enables standardised communication between several tractors and implements. A huge step forwards in convenience, efficiency and cost reduction.

Only one terminal for multiple machines

You no longer need a separate terminal for each machine, you can use just one terminal for multiple machines. This means that you can immediately connect the machines “plug & play” to an ISOBUS tractor. Using its control and operating settings, the terminal brings the implement into view automatically.

Every AP DUBEX machine is equipped with an ISOBUS jobcomputer. This SPRAYER-Controller MIDI is an ISOBUS jobcomputer that handles the complete control of the machine. Depending on the sprayer’s equipment, one or more jobcomputers will be installed.

You can choose between several Müller or Trimble terminals. All terminals contain as standard the “ISOBUS-UT-UNLOCK” which means that all machines with an ISOBUS Jobcomputer can be controlled by these terminals. Usually the terminals are combined with a joystick that brings you the most important functions within easy reach. Additionally, multiple apps on these terminals can be activated to increase the functionality. Naturally you can, in consultation with us, also have AP Dubex machines that are provided with an ISOBUS-Jobcomputer controlled by an ISOBUS terminal of a different brand.

Spray booms

The basic range contains spray booms with a working width up to 27 m, in the “heavy” range they are available from 27 to a maximum of 45 metres. The booms are completely constructed from steel, strong yet light. All AP Dubex spray booms are equipped with the proven “Superbalans” system. A unique system, in which the boom is freely suspended with hardly any movement being transferred to the spray boom. The spray boom always balances independently and quickly. Furthermore the spray boom will react quickly when you correct the balance position.

The lifting cylinder includes an accumulator. This accumulator damps any unevenness in the surface so that vertical movements of the frame will not result in vertical movements in the spray boom. This provides a constant spray height and protects the spray boom against peak loads.

Swing protection

Besides moving in a vertical direction, the spray booms also move horizontally. For this reason the AP Dubex field sprayers are equipped with an innovative “Anti-Swing-System”, that effectively suppresses the forward and backward movement of the boom.

Strong air spring dampers damp this movement. From 40 m working width, rubber dampers are installed between the left and right boom section to ensure that swinging during speed alterations is reduced significantly and your distribution remains at a constant over the entire working width.

Nozzle holders and tips

Next to all common nozzle holders AP DUBEX also offers Airtec twin fluid nozzles, air assist and the WAVE system. The section layout has a standard design, but can also be designed to your specific requirements.

Off center nozzles with wide throw width characteristic and for border application are available both manually and electrically controlled.